Factors for Selecting a Low- or Medium-Voltage Electric Motor

Low-voltage motors are often a preferred choice due to familiarity with products and available services, as well as the typically lower cost of individual components. However, as horsepower (hp) increases, there can be advantages to moving to a medium-voltage motor. Low-voltage motors typically go up to 1,000 hp while medium-voltage motors can cover 250 hp and higher.

Furthermore, in special variable frequency drive (VFD) applications, low-voltage motors can go up to or even over 5,000 hp. This high rating is preferably above the National Electrical Manufacturers Association (NEMA) low-voltage limit of 600 volts but still under International Electrotechnical Commission (IEC) low-voltage limit of 1,000 volts.

Knowing when to select the right motor for an application can save users time, space and money. Here are some areas to consider when choosing between low- and medium-voltage electric motors.

Cabling

In low-voltage motors, as the hp range increases, the size of cabling increases to handle the increase in amps. With conductors being a copper component, this increase in wire gauge can add cost, especially on longer cabling runs across a large facility or over a long distance to a remote pumping station. This increase in diameter also makes turn radii larger, which increases the difficulty in making connections within the terminal boxes. This can be time-consuming and introduce additional risk to the maintenance crew during initial setup of the motor.

A lower current in medium voltage motors allows for smaller cables (leads) even at higher hp. The use of smaller gauge leads reduces the cost per foot for those long-distance connections to remote pumping stations. Also, during the motor connection procedures, the small gauge wires are easier to work with and connect within the motor terminal box. This can reduce the maintenance crew’s time in making the connections and reduce the risk of damage to the cables.

The cost of copper as a commodity and the difference in thickness of leads sized for low-voltage machines versus medium-voltage machines can be so large that this can be the primary determining factor in what voltage service is specified. The higher cost of medium-voltage equipment can easily be offset in applications with long cable runs from distribution.

Size

When space is a consideration, more than motor size should be reviewed as the choice between a low- or medium-voltage motor that has an impact on the components in the entire system.

Low-voltage drives are smaller than medium-voltage drives when variable speed applications play a role in the motor selection. However, above 1,000 hp this ratio starts to flip, and drive size may be comparable or even smaller. Due to lower amps, medium-voltage motors also enable the use of smaller supply side switch gear, supply transformer and controls.

Windings

Further reading:

What is the difference between welding cable and normal cable?

Precision and Reliability: The Essentials of Medical PCB Assembly

Do String Lights need to be UL certified?

What is an LCD Display : Construction & Its Working

Do Wireless Car Chargers Drain Car Battery?

Installing a Suspension Clamp: A Comprehensive Guide

How Automotive Starter Battery Works?

To prevent short circuits and preserve the longevity of medium-voltage windings, they are commonly produced using a form wound insulation system. The insulation system is sealed using a vacuum pressure impregnated (VPI) system, which fills the voids in the coils to protect from contamination. The coils are organized outside of the stator core to ensure the ideal spacing of turns, which allows for air flow around the coils to improve heat transfer. It is a more labor-intensive process but is well suited to the rigors of the voltage impulses of a medium-voltage system. Additionally, due to the smaller conductors used in the windings, there is the possibility of having more turns, so there is greater flexibility in the electrical design, making it possible to achieve specific performance characteristics.

In low-voltage motor windings with larger diameter conductors, there are more limitations to the electrical design but less need for the precisely ordered coils required to withstand medium voltage. Because of this, low-voltage machines can use a more cost-effective random or mush wound design with a thorough dip-and-bake in varnish that is often coupled with a vacuum impregnation of the winding to ensure that the insulating material fills all voids. The result is a low-voltage insulation system that is capable of exceeding industry standards for longevity while achieving the performance characteristics necessary for a broad range of applications.

Like all good questions, whether to pick a low- or medium-voltage motor for a pump system does not have an easy answer. There are several factors to weigh, including site and installation specifics that will impact what voltage service is best for a given project. When selecting a motor for an application, evaluating these three factors should provide the best all-around motor for the facility.

4 Tips For Selecting a DC Motor or Gear Motor For Any Application

How to select a DC motor for a particular application?

There are a few things to consider when it comes to the motor selection process. We all know that electric motors convert electrical energy into mechanical energy, but there are a lot of options on the market to choose from. The motor selection process can be a daunting process: we are here to help get you focused and headed in the right direction with our 4 Motor Selection Tips.

As world-leading DC Motor and Gear Motor design experts, we are here to get your next project “moving”. Our team of dedicated application engineers can assist and answer any questions you may have, just use the live chat feature below to get in touch or give us a call.

Find Your Solution

Tip # 1: Determine Your Speed, Torque and Voltage First

The three main specifications you will need to know for any DC motor application are voltage, speed and torque. Once these aspects are determined, you are now ready to get started on your journey to select the ideal motor solution. The key is to use a motor that is operating at or near its maximum efficiency.

Motor voltage should also be defined at the start of the motor selection process. Motor voltage will be determined by your electrical power source, for example a 12-Volt battery or power supply.The nominal voltage for DC motors is typically either 12 or 24VDC.

Rotational speed is important for any motion control application. The rated or on-load motor speed is how fast a DC motor will operate once a load is applied. The constant speed and maximum speed that the motor needs to operate at are important to know.

Motor torque is the amount of load the motor’s output shaft can overcome at a given point. The torque and speed of a motor are directly related to one another, as one increases the other decreases. The rated torque, or on-load torque, needs to be defined just like the speed. Another important aspect of torque is the motor’s stall torque or peak torque.

The relationship between torque and speed can be best understood by evaluating a motor’s performance curve, commonly found with the motor specification.

Choosing a motor or gear motor that meets both your speed and torque requirements is crucial in selecting an efficient motor for your application.

Tip # 2: Balance Size vs. Performance

Proper motor size is important for every application but it can become an issue if a certain performance is required. Typically, larger motors are more powerful than their smaller counterparts. Depending on your application requirements, you may have to sacrifice certain performance characteristics to help accommodate the size constraints.

By utilizing different types of motors and motor technologies, like brushless motors or motors with permanent magnets, there are endless possibilities to help meet the size constraints for the majority of applications.

Tip # 3: Gear Motors Offer More Torque

Sometimes you need more torque than is physically possible to get out of a standard DC motor. Utilizing a DC gear motor will result in increased torque and reduced speed, which is all dependent on the gear ratio that is used. There are 3 basic types of gear motors: spur gear motors, planetary gear motors, and worm gear motors. Each gearhead type has its own distinct advantages.

You can add a gearhead to stepper motors, brushless DC motors, as well as brushed DC motors. To learn more about the distinct differences between the different gear motor types, check out our design note: Planetary Gear Motors Vs. Spur Gear Motors.

Tip # 4: Define your Duty Cycle

Your duty cycle will dictate which motor type is best for your application or device. Operating times and dwell times, as well as directional rotation, are key aspects of your duty cycle. The duty cycle should be defined at the beginning of the motor selection process.

Intermittent duty cycles are encouraged for most industrial applications to help extend the useful life of a motor or gear motor. Continuous use is still acceptable but you need to make sure the motor is operating at its peak efficiency.

Contact Engineering

Discuss your requirements with our engineers today!

Our team of dedicated application engineers are here to assist at any stage throughout your design cycle. Feel free to utilize our Industrial Motor Selection Tool to get started! ISL Products offers a wide range of value added component solutions, so contact us today!

Factors for Selecting a Low- or Medium-Voltage Electric Motor

4 DC Motor & DC Gear Motor Selection Tips

Further reading:What industries benefit from touch screen industrial PCs?

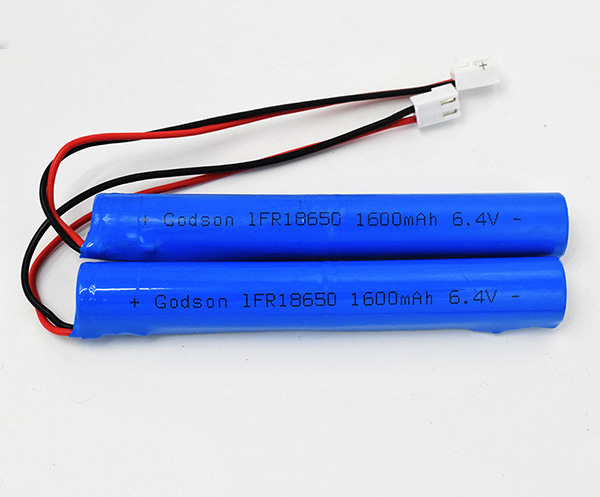

Versatile Applications and Advantages of LiFePO4 Batteries

How much do you know about alkaline batteries?

How does an Android Panel PC work?

PTC Heating Element for Thermostat: Innovation in Temperature Control

TFT Displays: the Future of visual technology

Unveiling the Characteristics and Types of Copper Cables

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

Comments

0